-

Sale!

Tesla Model S EV Battery

$6,999.00 – $14,500.00Price range: $6,999.00 through $14,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Tesla Model X EV Battery

$7,999.00 – $14,500.00Price range: $7,999.00 through $14,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

2018-2021 Tesla Model 3 Battery Replacement

$8,999.00 – $14,500.00Price range: $8,999.00 through $14,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

2021-2025 Tesla Model 3 Battery Replacement

$8,999.00 – $9,999.00Price range: $8,999.00 through $9,999.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

2018-2021 Tesla Model Y Battery Replacement

$8,999.00 – $14,500.00Price range: $8,999.00 through $14,500.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

2021-2025 Tesla Model Y Battery Replacement

$8,999.00 – $14,500.00Price range: $8,999.00 through $14,500.00 Select options This product has multiple variants. The options may be chosen on the product page

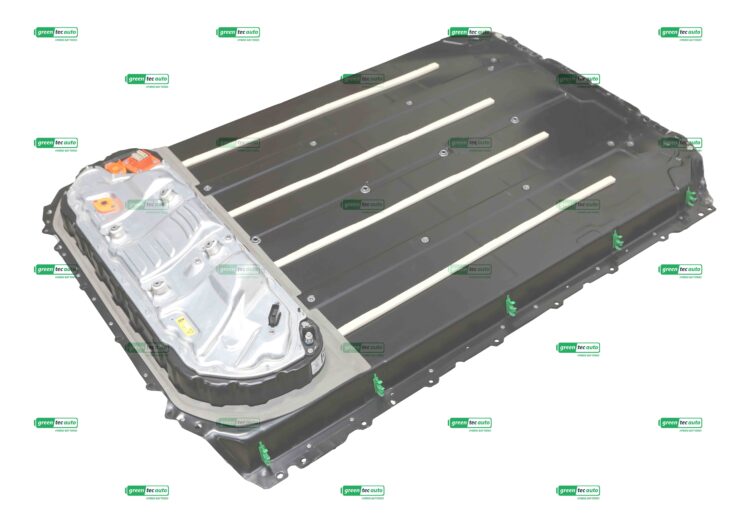

At Greentec Auto, we see electric vehicle batteries every day—healthy ones, worn ones, and unfortunately, damaged ones. But every so often, a battery comes across our bench that tells a much bigger story about design, real-world use, and the future of EV repair. This Tesla Model S Plaid battery is one of those cases.

This particular battery came from a customer whose situation was, frankly, frustrating. The vehicle was driven normally at first, but after a short period of time, a check-engine warning appeared. When the car was taken to Tesla for inspection, the verdict was water damage—and the warranty claim was denied. The reason? Negligence.

From what we were able to determine, the vehicle had been driven through deep puddles at speed. In a high-performance vehicle like the Model S Plaid, acceleration plays a role. When you combine speed, water depth, and pressure, water can be forced into areas it was never meant to reach. In this case, water likely entered through the battery’s umbrella cups or adjacent access points—components that are plastic, relatively flimsy, and vulnerable under the right conditions.

One of the biggest misconceptions we see is that a battery needs to be flooded to fail. That simply isn’t true. It does not take gallons of water to cause catastrophic damage. In many cases, a relatively small amount of moisture is enough to compromise electrical connections, corrode components, and trigger a complete failure. That’s exactly what happened here. The car became undrivable, and the battery had to be replaced entirely—at significant cost to the customer.

Performance vs. Repairability

There’s no denying it: from a performance standpoint, the Tesla Model S Plaid is impressive. The power delivery, acceleration, and engineering behind the driving experience are remarkable. However, from the perspective of a remanufacturing and repair company, this battery represents one of the most challenging designs we’ve encountered.

The issue is not performance—it’s serviceability.

When we opened this pack, two design choices immediately stood out. The first is how the modules are interconnected. In earlier Tesla Model S packs, as well as Model 3 and Model Y packs, modules were fastened together using mechanical fasteners between each module. While that required more labor during assembly, it also made disassembly and repair far more realistic.

In the Plaid pack, those fasteners are gone. Instead, the inter-module connections are laser-welded. From a factory automation standpoint, this makes sense. Robots can do this quickly and consistently. But for repair, it creates a serious obstacle.

To remove a single failed module, those welds must be carefully cut or drilled out. Beneath those welds? Live cells. That means absolute precision is required. Too aggressive, and you risk damaging the cells. Too cautious, and you’re left with poor connections when reassembling. Even with advanced equipment like laser welders—which we already have—dialing in the exact settings for this specific application is extremely time-consuming and costly.

And that’s just to remove the module. Repairing it and reinstalling it introduces another layer of complexity.

The BMS Challenge

The second major issue is the Battery Management System (BMS) layout. In this pack, the BMS runs lengthwise along the module, with all the cell tap connections laser-welded in place. Once again, laser welding improves manufacturing efficiency but dramatically complicates repair.

If a BMS connection fails, accessing it requires specialized equipment and extreme care. Set the laser too strong, and you burn through the material or damage the BMS. Set it too weak, and you end up with unreliable connections that can cause problems later. Achieving the right balance often requires multiple test passes—and that’s assuming you already have the tooling and expertise.

Because of this, the Model S Plaid battery is not just difficult to repair—it is one of the most labor-intensive EV batteries we’ve ever seen. That translates directly into higher repair costs compared to other vehicles.

What About Second-Life Use?

Second-life battery applications—such as home energy storage, off-grid systems, or electric conversions—are an important part of sustainable EV ecosystems. Unfortunately, this battery is not well-suited for that future.

Each module in this pack is roughly 82 volts, with five modules total. That voltage and physical size make it impractical for common second-life applications like golf carts or residential storage. Beyond that, the same laser-welded bus bar design that complicates repairs also complicates reuse.

You can’t simply bolt modules together with standard bus bars. Welding is required. That’s not something most individuals or small shops can do safely or accurately. As a result, unless these batteries are reused in their original vehicle configuration—or in very specific, industrial use cases—the most realistic outcome is discharge and recycling.

Bus Bars and Current Flow

One interesting design detail worth mentioning is the battery’s bus bar layout. You’ll notice that one bus bar is significantly thicker than the other. This comes down to current demands.

The thicker bus bar is designed to handle the high current associated with supercharging and power distribution across the length of the pack. Other connections—such as those feeding the motors—require less current and therefore use narrower conductors. It’s an efficient design electrically, but again, it adds complexity when disassembly and resealing are required.

Speaking of resealing, despite extensive use of adhesives and sealants, water still found its way into this pack. That’s unfortunate, because those same adhesives make opening and closing the pack far more difficult during service.

Final Thoughts

This Tesla Model S Plaid battery highlights a growing challenge in the EV world: the gap between cutting-edge performance and long-term repairability. As manufacturers push for higher automation and structural integration, independent repair and second-life reuse become more difficult.

At Greentec Auto, we’re actively working to overcome these challenges. We’re investing in equipment, developing new processes, and continuing to explore ways to safely and effectively service even the most complex battery designs. But cases like this make one thing clear—battery design decisions today will have long-lasting impacts on repair costs, sustainability, and consumer ownership experience.

If you have questions about this battery, EV water damage, or battery repair in general, feel free to leave a comment. We’re always happy to share what we’re learning from the inside of these packs.